A Powerful Tool for Fiber Patch Cord Production: The Fiber Patch Cord Manufacturing Machine with Built-in End-face Polishing Module

With the rapid development of optical communications, fiber patch cords, as a critical component of optical networks, have a direct impact on network transmission stability and signal loss. However, the production process for fiber patch cords is complex and requires high precision, making traditional manual methods inadequate for the demands of modern high-speed optical networks. This is why the Fiber Patch Cord Manufacturing Machine has emerged as an indispensable core piece of equipment in the fiber optic manufacturing industry.

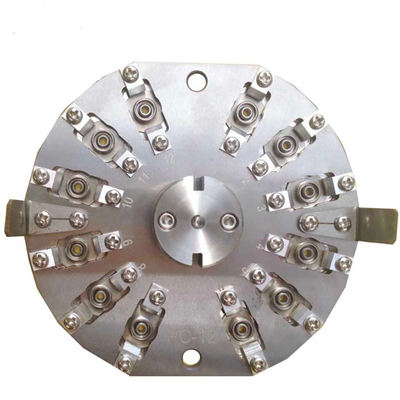

The Fiber Patch Cord Manufacturing Machine is a fully automated production machine that integrates fiber end-face cutting, stripping, end-face polishing, ferrule fixing, and end-face inspection. Its greatest strengths lie in its high efficiency and precision, significantly improving the yield rate of fiber patch cords and reducing the instability associated with manual operation. The built-in end-face polishing module is a key feature of this type of equipment.

Fiber end-face polishing is one of the most critical steps in the fiber patch cord manufacturing process. Proper end-face polishing not only ensures low optical signal loss and high echo suppression, but also effectively extends the life of fiber connectors. Traditional polishing methods often rely on manual labor, which can lead to problems such as end-face unevenness, angle deviation, and residual impurities. The Fiber Patch Cord Manufacturing Machine, however, features an automated polishing module that precisely controls polishing pressure, angle, and rotation speed to achieve high end-face flatness and low insertion loss. Whether processing single-mode or multimode fiber, the machine consistently produces high-quality fiber end-faces to meet the needs of diverse network environments.

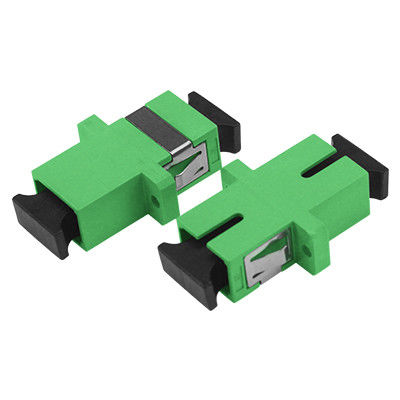

Furthermore, these machines typically support a variety of fiber types and connector specifications, such as SC, LC, FC, and ST, flexibly adapting to various production line layouts. Furthermore, the machine's intelligent control system monitors production parameters in real time, performs quality inspections on each fiber patch cord, and records key data to ensure product consistency and traceability. For large-scale manufacturers, this means significantly improving production efficiency and capacity while ensuring quality.

Another major advantage of using the Fiber Patch Cord Manufacturing Machine is reduced labor costs and training requirements. Traditional manual production of fiber patch cords requires extensive operator experience, while automated machines require minimal training, significantly reducing reliance on personnel. The equipment's modular design also facilitates future maintenance and upgrades. Users can flexibly add or replace polishing and cutting modules based on production needs, ensuring long-term, efficient operation of the production line.

Overall, the Fiber Patch Cord Manufacturing Machine, combined with its built-in fiber end-face polishing module, provides an efficient, stable, and precise solution for fiber patch cord production. Whether used by telecom operators, data centers, or fiber optic manufacturers, this equipment can significantly improve product quality and production efficiency, making it an indispensable tool in modern fiber optic manufacturing. With the continuous advancement of optical communication technology, high-quality and efficient fiber patch cord production equipment will become a key driver of industry development.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!