Optic fiber cleaner for SC connector cleaner cleaning pen for telecommunication

Descriptions

Fiber Optic Cleaner-Mini Designed to specially work well with the LC,MU,SC, FC, ST and MPO connectors, this instrument cleans the ferrule end faces removing dust, oil, and other debris without nicking or scratching the end face.

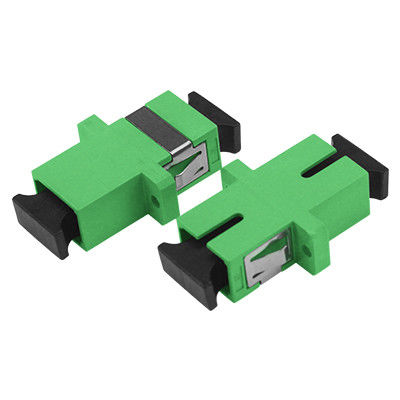

The SC&FC Cleaner is a high-performance device designed for cleaning the ferrule end-faces of SC&FC connectors. Cost effective tool for cleaning fiber end-faces without the use of alcohol. The SC&FC connector cleaner is designed to clean both exposed jumper ends and connectors in Adapters.

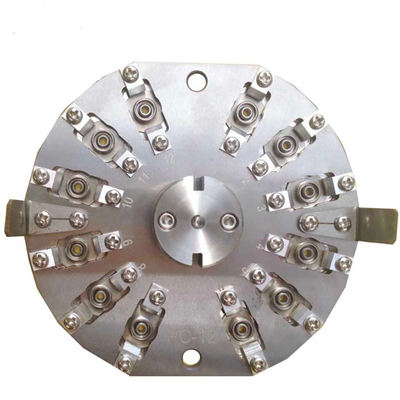

Structure Drawing & Specification

AS for the structure of cleaner, It can be divided into the cover guide cap, guide cap, cleaning tip and a body part. Cover guide cap protects cleaner from dust; guide cap is used for connecter cleaning; cleaning tip can be extended for adapter cleaning; cleaning body is used for adjusting the position of tip as standard position or extended position.

Features

Cleans connectors on jumpers and in adapters

Ergonomic, comfortable design with single action cleaning

Effective on a variety of contaminators including dust and oils

Disposable with 800+ cleanings per unit

Made from anti-static resin

Cleaning micro fibers are densely stranded and debris free

Extendable tip reaches recessed connectors

Cleaning system rotates 180 for a full sweep

Audible click when engaged

Specifications

| Model Number |

SC-250-C |

| Classification Color |

Green |

| Applicable Fiber Optic Connector & Adapter |

SC,FC,ST,E2000 |

| Dimension(mm) |

W17.5*H17.5*L165 |

| Function/Handling type |

Fiber Cleaner |

| No. of Cleanings |

>800 times |

| Cleaning Method |

Dry(Cleaning the Zirconia ferrule endface with

cleaning clothwith no chemical or solvent)

|

| Weight |

0.3KG |

Application

The SC&FC 2.50mm One-click Cleaner is dry cloth cleaners specially designed to clean single connector residing in an adapter, faceplate or bulkhead. They are simple to use and highly effective at removing oil and dust contaminants. That can negatively impact optical performance.

Why Should We Clean the Connectors?

Research has shown over 85% of fiber optic network failures in data centers, campus, and other optical communication facilities are caused by contamination on the optical connector end face.

For best optical performance, it is imperative that all optical fiber connections are clean and free of contaminants. Fiber optic cleaning products is being highly recommended as a kind of very important tool for electrical manufactures. One of the most basic and important procedures for the maintenance of fiber optic systems is to clean the fiber optic equipment.

Fiber optic connector cleaner is designed to effectively and quickly clean connector endfaces, both the unmated patch cord and through the adapter. It cleans the ferrule end faces removing dust, oil, and other debris without nicking or scratching the end face. It is very easy to use and suitable for all LC/ MU connectors and ferrule

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!