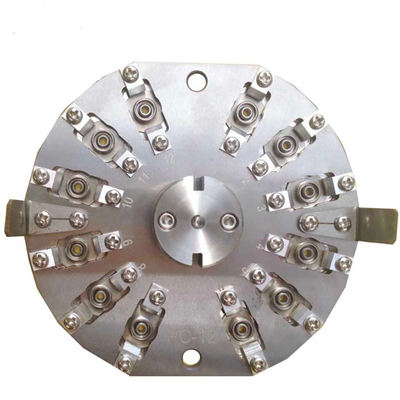

Semi-automatic Fiber Optic Epoxy Injection Machine for LC SC ST FC Connector ferrule Fiber Optic Epoxy Dispener

Model:CLX-DJ02

Place of Origin:ShenZhen,China

Description

CLX-DJ02 semi-automatic dispenser is controlled by a film tap switch.Can adjust manual, semi-automatic state, the use of digital timing controller accurate to seconds, the correct control of flow, will not waste liquid material, it is easy to change each infusion volume and infusion time.It can solve many problems in stock development. It is simple to use and easy to operate. Equipped with vacuum suction function, it is not easy to fatigue, no waste, and has a wide range of use.

Specifications

| Time Setting |

0.001 sec to 9.999 sec |

| Injecting time |

0.007 sec to 9.999 sec (with air pressure) |

| Cycle break |

0.1 sec to 9.9 sec |

| Input Pressure |

1bar to 7bar (1 bar =1.01972 kg/cm2 =14.5038 psi) |

| Output Pressure |

0.1 bar to 7 bar |

| Repeat Accuracy |

0.00005 sec |

| Minimum Droplet |

0.005 ml |

| Frequency |

No fewer than 600 times per minute |

| Input Voltage |

110VAC+/-11VAC 50Hz ; 220VAC+/-22VAC 50Hz |

| Power Consumption |

Less than 15 Watt |

| Size |

70 mm x 210 mm x 256 mm |

| Net Weight |

Less than 4 kg |

Attention and maintenance:

1, Air pressure cant be more than 7bar(10psi), working air pressure cant be more than 5.5bar (78psi), if the working air pressurer is more than 4 bar, pls use the original parts from the manufacter.

2, The liquid material must be stired evenly before putting to the cyliner needle. It will be better if the liquid material can be stored at the stable temperature of 5 degree centigrade to make sure there is no big change in the density of the liquid material. If the density of the liquid is so high, ( it means the liquid is so viscous, it may be hard to spit out). If the liquid need to be diluted, pls compliant to the instruction of the liquid material manufacture.

3, Dont sharply increase the Vacuum, otherwise, the liquid will be pulled in the catheter by the vacuum. The qty of the vacuum pumpback rely on the air pressure level, working cycle, qty of the liquid to spit. If the qty of the vacuum is too much, the piston will be overset, disturbing the normal work.

4, Avoid to overset the liquid cylinder, otherwise, the liquid will flow to the air cylinder to destroy the internal aprt.

5, Pls clear the stuff left in the cylinder needel when needed. Otherwise the stuff will become hard, then disturbing the vacuum pumpback and stop the cylinder needle.

6, After using the machine, the cylinder needle need to be cleaned every time, otherwise, it is difficult to unload the needle when the liquid becomes hard. Normally, it is easy to remove the liquid from the inside of the cylinder needle, just dipping the parts in the hand water for 5~10minutes, all the part will be cleaned.

7, Pls disposal the used needle and cylinder needle at appropriate place to avoide some i nappropriate liquid pollution

FAQ

1.Are you a factory or a trader?

......we are factory.

2.What is your MOQ?

......MOQ 1 piece.

3.Do you provide sample services?

......Yes, we will provide samples(Samples at prices announced by chuanglixun).

4.How will you ship to me?

....... We will spend 4 to 6 days via DHL or FedEx. Properly extended based on order quantity

5.How do we pay

......Book in advance or multiple payment methods such as T / T and T / L.

6.How long is your product warranty?

......The warranty period is 1 year (the warranty period will provide free repairs, except for consumables). After the warranty period, accessories will continue to be provided and will be charged at cost.

7.Do you provide customized services?

......Yes, we provide customized services, According to customer requirements and description

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!