Horizontal Wholesale FTTH Fiber Pigtail Patch Cord Fiber Optic Connector Heat Fiber Optic Epoxy Curing Oven

Description

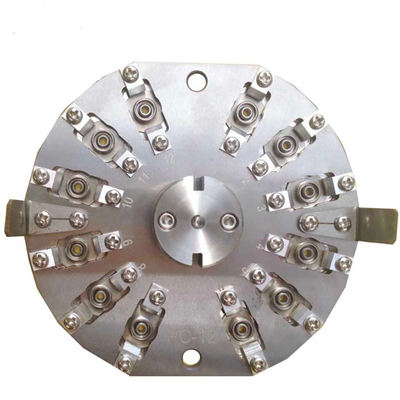

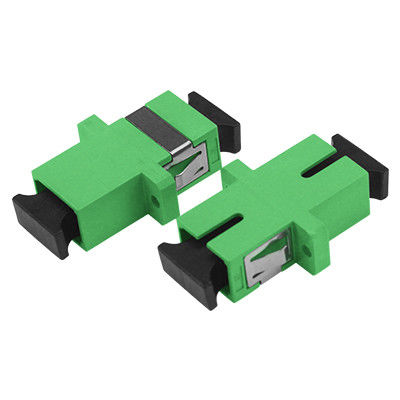

Curing Oven is a type of universal curing oven for fiber optic connectors, it is available for general connectors (such as FC/SC/ST, MU/LC) after glue injecting. The heating board could contain 100 connector ferrules at most. There is indicator light, timer and temperature indicator. Simply operation and perfect solidified effect.

Key Features

Input voltage: 220 VAC 50 Hz, or 110 VAC 50 Hz;

2> Horizontal Heating Board, convenient for putting ferrules and connectors;

3> High efficiency, 100 ferrules heating synchronously;

4> Indicator shows temperature and time, high precision for temperature control;

5> Automatically timing, and buzzer alarm reminding after time is up.

Operating Instructions

Connected to single-phase power supply , 200V AC, 5A;

Switch power to ON, the red LED lights;

Program settings:

Press SETUP to display the corresponding control button into the program settings, there are two settings, one for time, another one for temperature;

Temperature control: set the curing requires constant temperature, press UP and DWON to add and subtract, display the desired temperature then press OK button to enter the time control. Factory settings default temperature: 100℃;

Time control: when it shows entry time control, press UP and DWON to adjust the time, time is the time required for curing continued at a constant temperature. After adjusted the desired time, press OK to enter operation. Factory setting: 30 minutes;

Curing, put the fiber connector into curing fixture, placing it in oven, heating board then covered with dust cover;

Press OK, curing, curing furnace heating temperatures to the specified time, timer automatic timer, temperature should keeping constant, arrived at the designated time, curing oven stopped heating, curing cycle ends;

If need cure again, time and temperature still stay the same then put connectors into fixture, placing it in oven, press AGAIN for next cycle of cure;

If you need to change the time and temperature, enter SETUP, adjust them.

Technical parameters

| Dimension (mm) |

420 x 320 x 140 |

| Weight (kg) |

8.5 kg |

| Heating Temperature |

40 ~ 300 ℃ |

| Accuracy |

+/- 1 ℃ |

| Input Voltage |

100~120VAC, 50Hz / 200-240VAC, 50Hz |

| Power Consumption |

800 W |

| Warm-up Time (approx.) |

15 min |

| Connector Type |

1.25 mm / 2.50 mm ferrule, FC/ST/SC/MU/LC |

| Capacity |

100, 80 |

Attention

This device uses high-precision integrated circuit design, with PID function, need to prevent too hard and damage components during the processing.

If the device has any abnormal display, please notify the supplier for repair in time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!