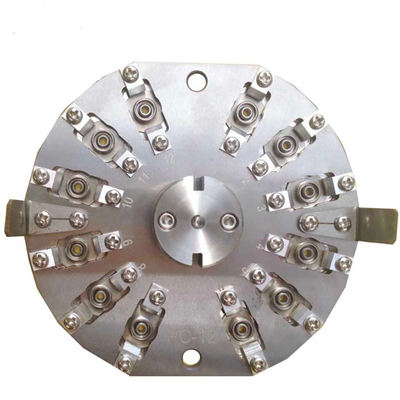

Fiber Polishing Machine Patch Cord Making Optic Polisher Grinding Connector Grinder Equipment

Model:CLX-02E

Place of Origin:ShenZhen,China

Product Description of Fiber Jumper Polishing Machine

The Fiber Optical Polishing Machine on The Base of International Universal Standards and Long-Term Hands-On Experience, It Exceeds Requirements for Gr-326 End Face Geometry, And This Fiber Optical Polishing Machine Adapt To Four Corners Compression And New I. P. C. Holder Technology Yields The Best Results In The Industry. No Variability in Result When Polishing 1 Or 24 Connectors, Jig Will Be Installed Stable, And Compact Size.

This Fiber Optical Polishing Machine Can Process Excellent Connector End Force Polishing Quality. Our This Type of Fiber Optical Polishing Machine Designed for Volume Production, High Productivity. For More, The Fiber Optical Polishing Machine Can Save Material and Low Cost for Polishing.

Specifications of Fiber Optic Polishing Machine

| 1. Model Number |

CLX-02E |

| 2. Machine Size |

285*220*338mm |

| 3. O.D. of Rotation Plate |

127 mm(5 inch) |

| 4. Time Settings |

99 min 99 sec (Max) |

| 5. Speed for Rotation Plate |

80 rpm |

| 6. Height of Plate Jumpiness |

<10 um |

| 7. Pressure Configuration |

21 ~ 36 N/cm2 |

| 8. Work Temperature |

10℃~40℃ |

| 9. Relative Humidity |

15%~85% |

| 10. Noice |

unloading Less 50 dB |

| 11. Libration |

Working Status 0.25g 5~100Hz 10min |

| 12. Stopping Status |

0.50g 5~100Hz 10min |

| 13. Power Input |

110~230 VAC 50Hz/60Hz |

| 14. Electric Power |

126W |

| 15. Net Weight |

27kg |

| 16. Materials |

stainless steel |

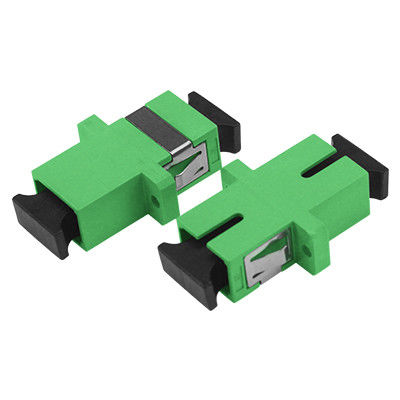

| 17. Lnsertion Loss |

≤0.20dB |

| 18. Return Loss |

≥55dB(UPC,PC) ≥60dB (APC) |

About shipping

We usually use DHL, FEDEX, UPS, EMS, TNT or Sea, these are the world's largest shipping companies, you can provide us with your courier account, we will help you choose the cheapest and the cheapest according to the quantity

FAQ

1.Polished ferrules could not reach required shape or quality.

(1)Film is used over 40 times.

(2)Water doesn’t be used.

(3)Films are not cleaned completely.

(4)Ferrules and jig are not fixed correctly.

(5)The distance adjustment between screw top and Plane A is not correct.

2.Bad quality for the polished surface.

(1)Film is used over 40 times.

(2)Polishing liquid is not used.

(3)Film is dirty.

(4)Ferrules are not cleaned completely.

(5)Scraped by film when pulling out the ferrules.

3.How can we guarantee quality?

(1)Always a pre-production sample before mass production;

(2)Always final Inspection before shipment;

4.What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,HKD,CNY;

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash,Escrow; Language Spoken:English,Chinese

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!