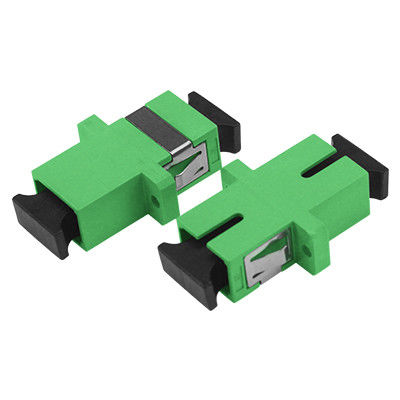

A fiber optic grinder is a device specifically designed for polishing various fiber optic connector products, primarily used to polish the end faces of ceramic fiber ferrules, such as patch cords, pigtails, bundled fibers, PLC splitter connectors, power fibers, plastic fibers, and pre-buried ferrules for optical fiber components. It is widely used in the optical communications industry and is irreplaceable. A mature production line in modern enterprises utilizes four or five fiber optic grinders, along with various FC/SC/LC/ST/MPO/MTRJ/MU polishing fixtures, fiber curing ovens, end-face inspection equipment, pneumatic crimping machines, and insertion loss testers, to form one or more production lines for the production of active and passive components such as patch cords, pigtails, and pre-buried ferrules.

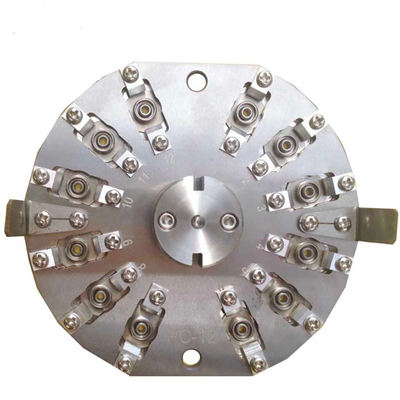

Fiber optic grinders are generally divided into two categories based on the pressure application method: center-pressure grinders and corner-pressure grinders. Center-pressure grinders transmit pressure from the center of the grinding fixture, with the polishing pressure varied by adjusting the weight position. An early representative of this type of machine is the Seiko Instruments OFL-12. This control method lacks precision and is generally used only for polishing low-end products. Center-pressure grinders typically have 12 heads, meaning they can polish 12 fiber ends simultaneously, resulting in lower efficiency than corner-pressure grinders. Corner-pressure grinders apply pressure from the four corners of the grinding fixture, achieved by adjusting the spring pressure on four columns. An early representative of this type of machine is the Seiko Giken SFP-550. Similar models are now available. For the past decade, Seiko Giken has dominated the high-end market, while the mid-range and low-end markets have been divided among various small and medium-sized manufacturers. Corner-pressure grinders typically have 20 heads in their fixtures and offer higher production efficiency than center-pressure models. In terms of regional distribution, optical fiber polishers in Central and Southern China used to primarily utilize center-pressurized polishers. In recent years, standard products have switched to four-corner pressurized polishers. East China primarily utilizes four-corner pressurized polishers. Optical communications in other regions are relatively backward and are not included in the statistics.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!